Canning Technology > | > Canning Technology > | > Integrated Fabricating >

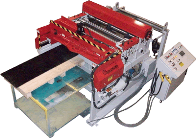

Econo-Slear

LIGHT TO MEDIUM DUTY COIL BLANKING SYSTEM

A low cost, easy to use, Multi-Blanking System that will remove coil set, slit to width, and cut to length in a self contained, compact unit.

Higher production is assured with the ability of this machine to make multiple slits to the material before it is cut to length.

Coil set is removed by the standard 4-roll straightener.

Specifications

Available widths 1219mm, 1524mm, 1828mm

Minimum material thickness .38mm

Maximum material thickness 2mm

Shear Strength 35 kg/mm2

Tensile Strength 47 kg/mm2

Yield Strength 55,000 psi (38.5 kg/mm2)

Roll Size 107 mm dia.

Line Speed 25FPM to 150FPM

Part Tolerance:

Length ± 3/4 mm

Slit Width ± .18 mm

Available Options

6- Roll Powered Straightener

Variable Speed Control

HVAC Beading

Recoiling

The EconoSlear systems produce blanks from coil stock including mild steel, pre-painted, embossed, galvanized, tin plate, aluminium, stainless steel and other ferrous or nonferrous metals. The EconoSlear blanking lines are equipped with IPI’s electronic controls for accurate, pre-set blank length and batch quality.

A host of labour saving accessories such as coil handing equipment, single and double decoilers, edge trimming, scrap choppers and a variety of blank stacking systems make the EconoSlear the industry leader in light and medium duty coil processing systems.

Specifications for the EconoSlear

Coil Width: Maximum 1830mm, Minimum 152mm

Material Thickness: Maximum 2.0mm, Minimum 0.4mm

Straightening Section: four roll powered straightener, six roll powered straightener optional

Drive: Two speed electric motor and gearbox

Email Us: sales@mftsa.co.za

Call Us: +27 (0) 83 273 8322